Double drop trailers are a game-changer in the world of heavy hauling. These specialized trailers offer unique advantages for transporting oversized or tall loads.

At Loyalty Logistics, we’ve seen firsthand how double drop trailers can boost efficiency and safety in freight transportation. This guide will walk you through the essentials of using these trailers effectively, from understanding their features to mastering loading techniques and driving best practices.

Understanding Double Drop Trailers

Definition and Key Features

Double drop trailers are specialized hauling equipment designed for transporting oversized or tall loads. These trailers feature a unique “well” section between the gooseneck and rear axles, which allows for increased vertical clearance while maintaining legal height limits.

The most distinctive feature of a double drop trailer is its lowered deck. This design accommodates cargo up to 12 feet high (significantly more than standard flatbed trailers). The well section typically ranges from 25 to 29 feet long and sits as low as 18 inches off the ground.

Choosing the right trailer for your freight is key to safety and efficiency. Our freight services cover flatbeds, step decks, double drops, and more, so we always match the right equipment to your load.

Double drop trailers can carry loads up to 45,000 pounds (depending on their axle configuration). This impressive weight capacity, combined with their lower center of gravity, makes them ideal for transporting heavy machinery and equipment.

Types of Double Drop Trailers

Several types of double drop trailers exist, each designed for specific hauling needs:

- Fixed Gooseneck: These trailers have a permanent connection between the trailer and the truck, offering stability for heavy loads.

- Removable Gooseneck (RGN): RGN trailers allow for easier front loading of cargo, making them perfect for transporting construction equipment like bulldozers and excavators.

- Extendable Double Drop: These trailers can extend to accommodate longer loads, providing flexibility for various cargo sizes.

Advantages Over Standard Trailers

Double drop trailers offer several benefits compared to standard flatbed or step deck trailers:

- Height Clearance: The lowered deck allows for taller cargo without exceeding legal height limits.

- Stability: The lower center of gravity enhances stability during transport, reducing the risk of tipping.

- Versatility: Double drop trailers can handle a wide range of cargo types, from heavy machinery to irregularly shaped items.

- Cost-Effectiveness: By accommodating taller loads, these trailers can help avoid costs associated with special permits or escorts often required for oversized loads.

Double drop trailers are particularly effective for industries like construction, energy production, and heavy manufacturing. Their unique design and capabilities make them an invaluable asset in modern logistics, offering solutions for challenging transportation needs.

As we move forward, it’s important to understand how to properly load and secure cargo on these specialized trailers. The next section will explore weight distribution considerations and proper tie-down techniques to ensure safe and efficient transport.

How to Load and Secure Cargo on Double Drop Trailers

Weight Distribution Mastery

Proper weight distribution is essential when loading a double drop trailer. The objective is to maintain stability and prevent damage to both the cargo and the trailer. Place the heaviest items over the trailer’s axles, and distribute weight evenly across the deck. This approach minimizes stress on the trailer’s structure and improves handling during transport.

When loading construction equipment, position the heaviest machinery directly over the axles, with lighter items towards the front and rear. This distribution helps maintain proper tongue weight (typically 10-15% of the total load weight).

Effective Load Securement

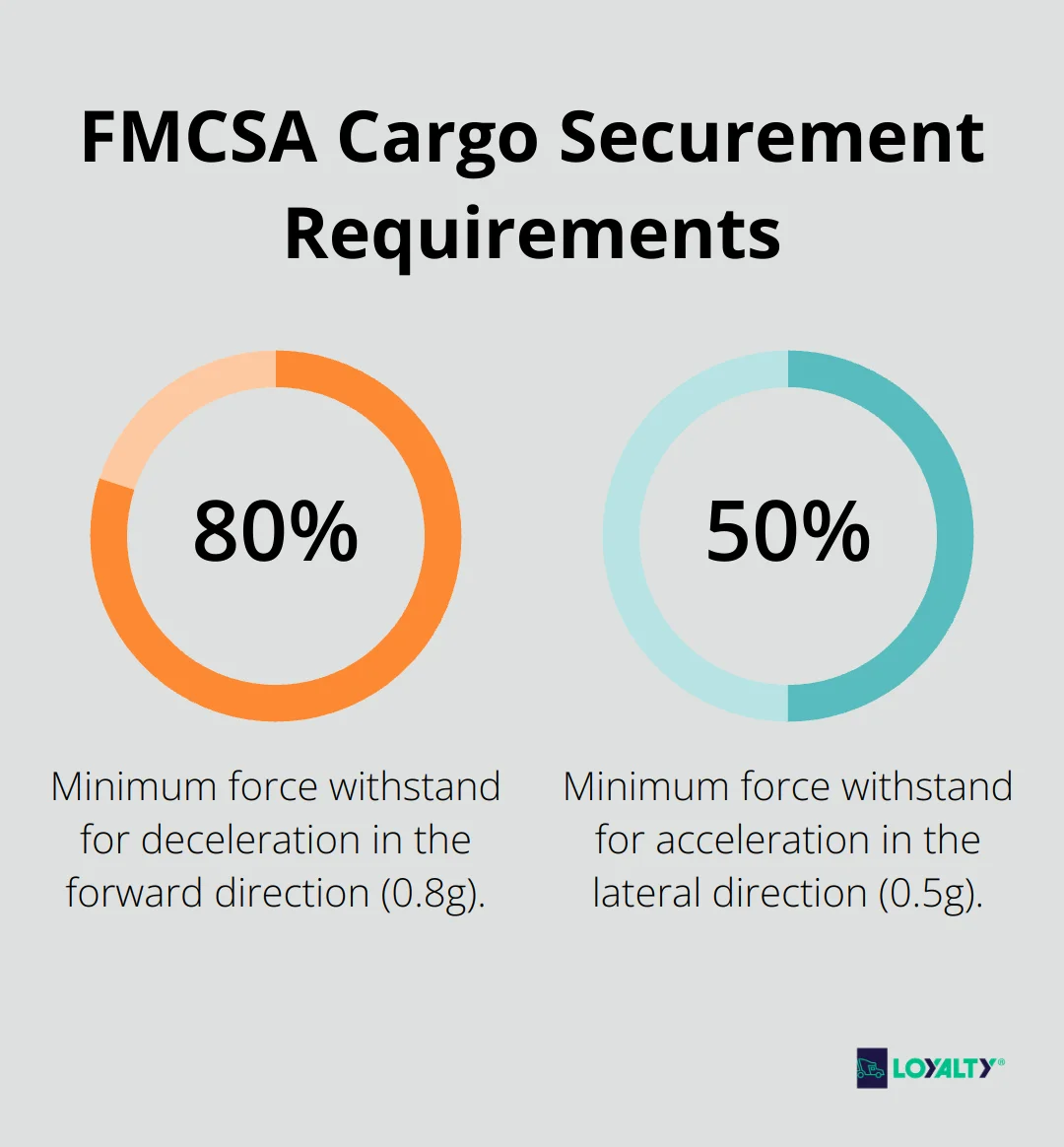

The Federal Motor Carrier Safety Administration (FMCSA) mandates that cargo securement systems must withstand minimum forces of 0.8g deceleration in the forward direction and 0.5g acceleration in the lateral direction.

Use a combination of chains, straps, and binders to secure loads. For heavy machinery, employ Grade 70 or Grade 80 transport chains (rated for working load limits of 4,700 lbs and 7,100 lbs respectively). Always use edge protectors where chains or straps contact sharp edges to prevent damage and maintain securement integrity.

Specialized Loading Equipment

Loading oversized cargo onto a double drop trailer often requires specialized equipment. Cranes and forklifts are common choices, but the selection depends on the specific cargo and loading location.

For example, loading a 40-ton excavator might require a 50-ton mobile crane. This provides ample lifting capacity and reach to safely position the equipment on the trailer’s well deck.

In some cases, custom-built ramps allow for drive-on loading of wheeled or tracked vehicles. These ramps can withstand the weight and traction of heavy machinery, ensuring a smooth transition onto the trailer deck.

Pre-Trip Inspection

Conduct a comprehensive pre-trip inspection before any load leaves the facility. Check all tie-downs and ensure the cargo is properly positioned and secured. This attention to detail contributes to maintaining high on-time delivery rates, even with challenging oversized loads.

The next crucial step in effectively using double drop trailers involves mastering the art of driving with these specialized vehicles. Let’s explore the best practices for navigating the roads with a double drop trailer in tow.

Mastering Double Drop Trailer Driving

Adapting Your Driving Technique

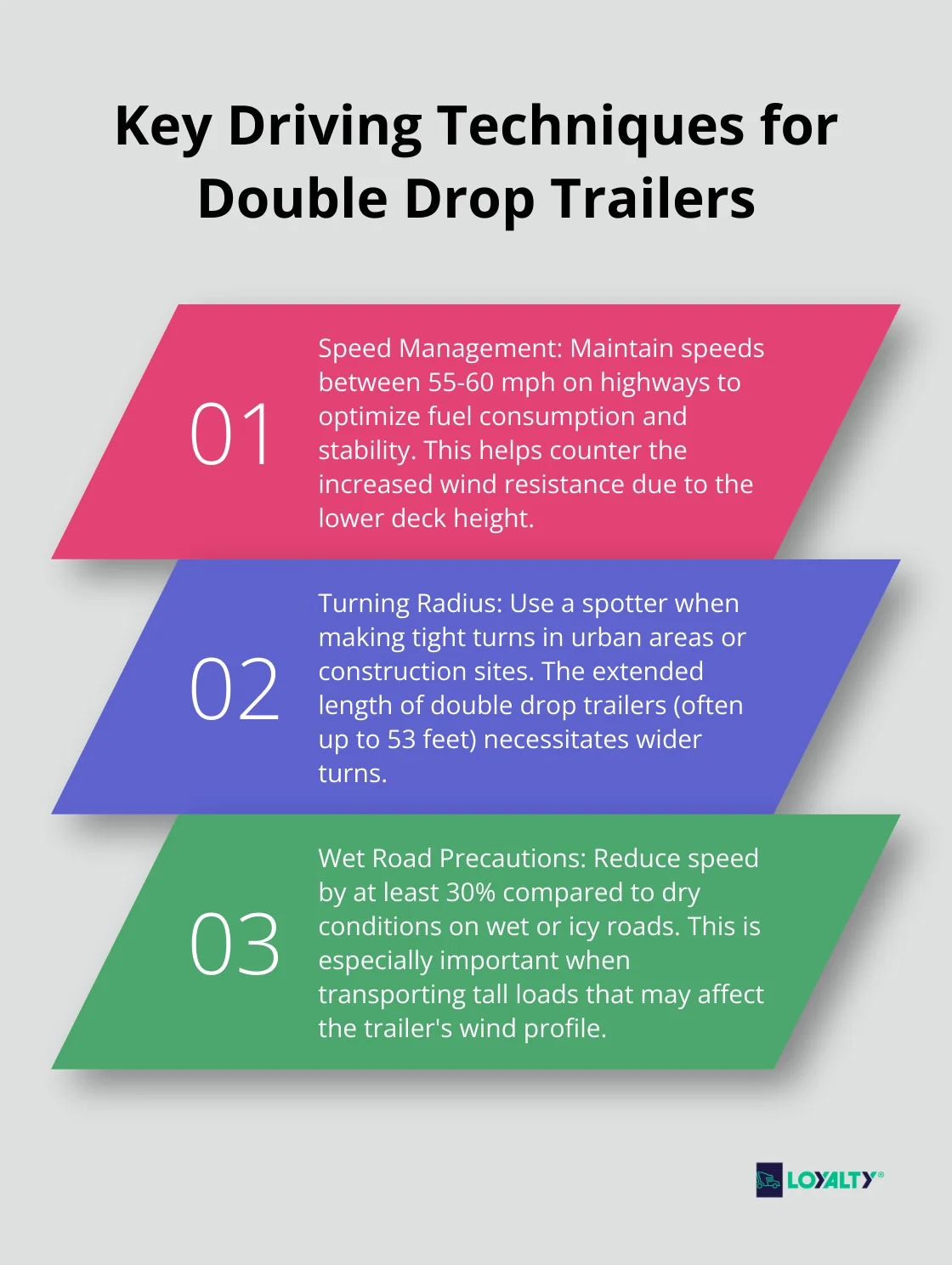

Double drop trailers operation demands skill, precision, and a thorough understanding of the vehicle’s unique characteristics. Speed management plays a key role in handling these specialized trailers. The lower deck height increases wind resistance, which affects fuel efficiency and handling. Drivers should maintain speeds between 55-60 mph on highways to optimize fuel consumption and stability.

Turning radius requires special attention. The extended length of double drop trailers (often up to 53 feet) necessitates wider turns. Use a spotter when making tight turns in urban areas or construction sites. This practice helps maintain a high damage-free delivery record.

Navigating Challenging Road Conditions

Double drop trailers offer excellent stability due to their low center of gravity, but they still require careful handling in adverse conditions. On wet or icy roads, reduce speed by at least 30% compared to dry conditions. This precaution becomes especially important when transporting tall loads that may affect the trailer’s wind profile.

When encountering steep grades, employ engine braking techniques to maintain control. Descend hills in a lower gear than you would use to climb them. This approach reduces wear on brake systems and enhances overall safety.

Maneuvering in Tight Spaces

Backing up a double drop trailer requires practice and patience. The American Trucking Association reports that nearly 60% of truck-related accidents occur during backing maneuvers. To mitigate this risk, conduct a thorough site survey before attempting to back into a loading dock or tight space.

Try the ‘Get Out And Look’ (GOAL) method frequently. This simple yet effective technique involves stopping the vehicle, exiting the cab, and visually inspecting the surrounding area before proceeding with a difficult maneuver.

For particularly challenging spaces, consider using a spotter. Clear hand signals and communication protocols between the driver and spotter are essential. A standardized set of hand signals across a fleet can significantly reduce miscommunication-related incidents (by up to 40% in some cases).

Weather Considerations

Weather conditions significantly impact double drop trailer operation. In high winds (over 30 mph), exercise extra caution, especially when carrying tall or lightweight loads. Strong crosswinds can affect trailer stability, so adjust speed accordingly and maintain a firm grip on the steering wheel.

During winter months, pay special attention to ice buildup on the trailer deck. This can create hazardous conditions for both loading and unloading operations. Regular checks and de-icing procedures become essential parts of the winter driving routine.

Final Thoughts

Double drop trailers offer unique advantages for transporting oversized and heavy loads. Their lowered deck design, high weight capacity, and enhanced stability make them essential for construction, energy production, and heavy manufacturing industries. Companies can improve their transportation efficiency and safety by mastering the use of these specialized trailers.

Safety should always take precedence when operating double drop trailers. Regular pre-trip inspections, thorough driver training, and adherence to best practices in loading and driving contribute to accident prevention and cargo protection. Weather considerations, especially in high winds or icy conditions, add complexity to double drop trailer operation.

At Loyalty Logistics, we understand the intricacies of double drop trailer operations. Our team has the knowledge and experience to handle diverse cargo types (from heavy machinery to oversized equipment). Whether you need to transport construction equipment or industrial tools, we strive to ensure your cargo reaches its destination safely and efficiently.

Need help choosing the right trailer for your next load?

We specialize in transporting oversized, tall, and heavy equipment safely across North America: