Choosing the right sea freight container size is a critical decision in international shipping. It impacts costs, efficiency, and the safety of your cargo. Making the wrong choice can lead to wasted space, higher costs, or even cargo damage, which is why having access to comprehensive freight shipping solutions becomes essential for optimizing your logistics strategy.

At Loyalty Logistics, we’ve helped countless businesses navigate this choice. This guide will break down the most common container sizes and help you select the best option for your needs.

What Are Standard Sea Freight Container Sizes?

Sea freight containers come in various sizes to accommodate different shipping needs. Let’s break down the most common options.

20-foot Containers: Compact and Versatile

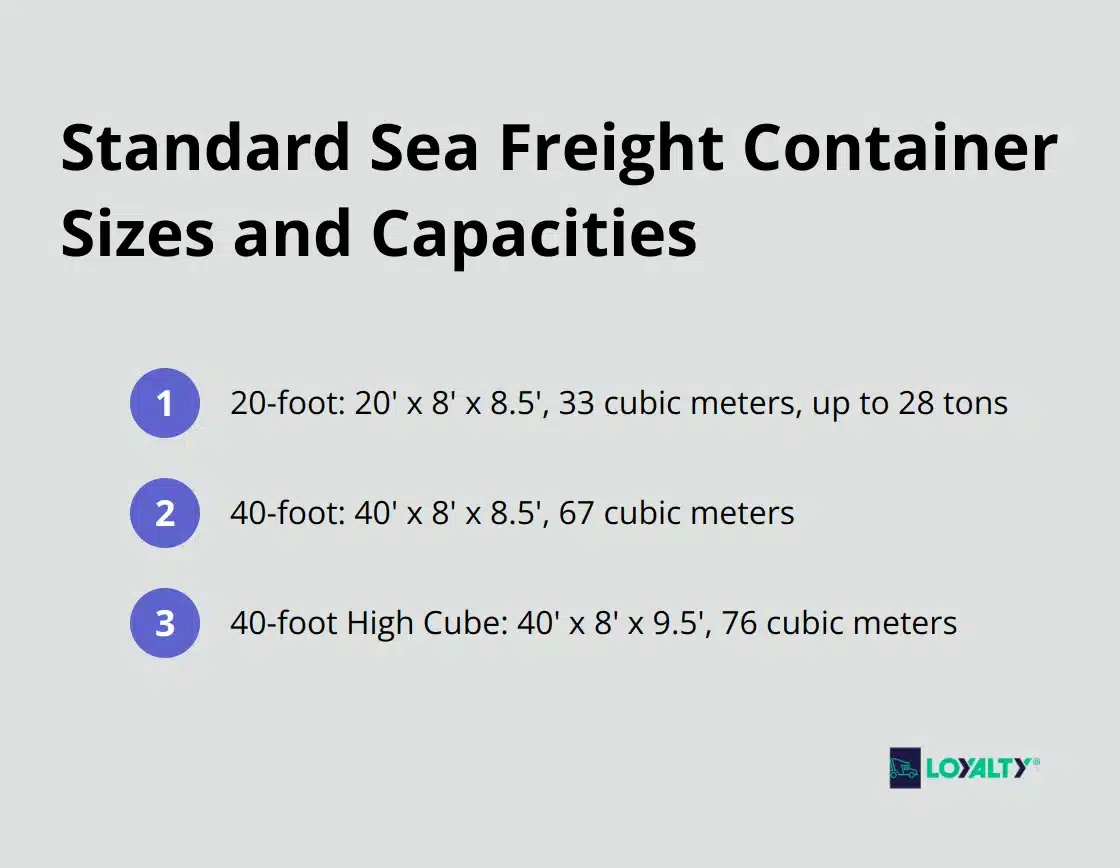

The 20-foot container is a popular choice for many shippers. It measures 20 feet long, 8 feet wide, and 8.5 feet high. With an internal volume of about 33 cubic meters, it’s perfect for smaller shipments or dense, heavy cargo. These containers can hold up to 28 tons of goods, making them ideal for items like machinery parts, steel, or bulk commodities.

40-foot Containers: Double the Space

For larger shipments, the 40-foot container is the go-to option. It’s twice the length of a 20-foot container but maintains the same width and height. With an internal volume of approximately 67 cubic meters, it’s excellent for bulky items or large quantities of goods. Many businesses prefer 40-foot containers for their cost-effectiveness when shipping high volumes, especially when optimizing full load shipments to maximize container utilization and reduce per-unit costs.

40-foot High Cube Containers: Extra Height Advantage

High cube containers offer an additional foot of height compared to standard containers. At 9.5 feet tall, they provide about 76 cubic meters of internal space. This extra height is valuable for tall items or when maximizing volume is a priority. Industries like automotive and electronics often opt for high cube containers to accommodate their oversized products.

Less Common Container Sizes

While 20-foot and 40-foot containers dominate the market, other sizes exist for specific needs. 45-foot containers offer even more space, while 10-foot containers are useful for smaller shipments or storage purposes. However, these sizes are less readily available and may come with higher costs or limited routing options. For businesses with smaller cargo volumes that don’t justify a full container, LCL (Less than Container Load) shipping offers a cost-effective alternative to these specialized container sizes.

Factors to Consider in Container Selection

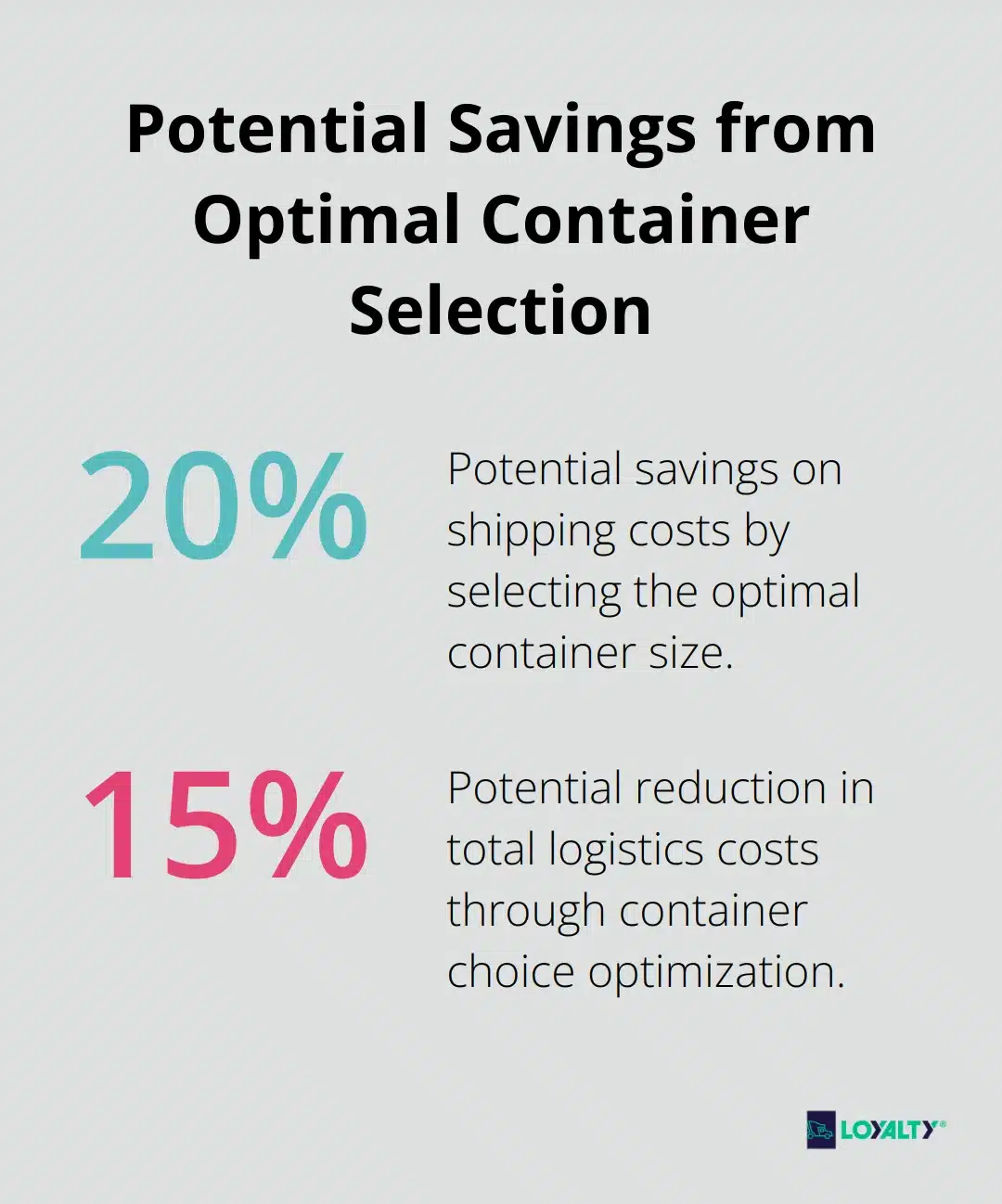

When choosing a container size, consider not just the volume of your goods, but also their weight distribution and handling requirements. The right choice can significantly impact your shipping costs and efficiency. Some businesses have saved up to 20% on their shipping costs by selecting the optimal container size for their needs (based on industry reports). Additionally, understanding international shipping requirements becomes crucial when different countries may have specific regulations or preferences for certain container sizes.

The container you choose affects more than just your immediate shipment. It can influence your entire supply chain efficiency. Companies that carefully consider their container choices often see improvements in their overall logistics operations, sometimes reducing transit times by up to 15% (according to logistics industry studies).

As we move forward, it’s important to understand that container size is just one piece of the puzzle. The type of goods you’re shipping and the specific requirements of your cargo play a crucial role in determining the best container for your needs. Let’s explore these factors in more detail in the next section.

How to Choose the Right Container Size

Assess Cargo Volume and Weight

The first step in container size selection involves accurate measurement of your cargo’s volume and weight. A recent study by the Journal of Transport and Logistics found that 30% of shippers overestimate their space requirements, which leads to unnecessary costs. To avoid this, use precise measurements and consider the stacking potential of your goods.

For example, if you plan to ship 500 boxes (each measuring 0.5 cubic meters), you might think you need a 40-foot container. However, if these boxes can stack safely, a 20-foot container might suffice, potentially cutting your shipping costs by up to 40%.

Understand Cargo Type and Special Requirements

Different types of goods have unique shipping requirements. Fragile items may need more space for protective packaging, while dense products like machinery parts can maximize a container’s weight capacity without filling its volume.

A survey by Freight Waves revealed that 25% of shipments arrive with some form of damage, often due to improper container selection. For instance, shipping electronics in a standard container without climate control can lead to moisture damage. In such cases, opting for a specialized container like a reefer (despite the higher upfront cost) can save thousands in potential losses.

Evaluate Route and Distance

The shipping route and distance play a key role in container selection. Longer routes often justify larger containers due to economies of scale. However, some ports have restrictions on container sizes they can handle. Understanding the complete shipping process, including cross-border shipping documentation requirements, becomes essential as different container sizes may require varying documentation approaches.

For example, shipping from Shanghai to Los Angeles in a 40-foot container might be 30% more cost-effective per cubic meter compared to a 20-foot container. But if your final destination is a smaller port that can’t accommodate larger vessels, the cost savings could disappear due to additional transshipment fees.

Consider Cost Implications

When selecting a container size, you must look beyond the immediate shipping costs. Factor in potential savings from reduced handling, storage, and transportation at the destination. Sometimes, choosing a larger container (even if it’s not full) can result in overall cost savings.

A logistics industry report suggests that companies who optimize their container choices can reduce their total logistics costs by up to 15%. This includes savings from reduced documentation, easier customs clearance, and more efficient warehouse management.

Seek Expert Advice

The complexities of international shipping often require expert knowledge. Professional logistics providers can offer valuable insights based on years of experience and data-driven analysis. Working with freight experts can help you navigate the nuances of container selection, taking into account factors you might overlook, from route optimization to regulatory compliance.

As we move forward, it’s important to recognize that standard containers aren’t always the best fit for every type of cargo. Some goods require specialized containers to ensure safe and efficient transportation. In the next section, we’ll explore these special container types and their specific uses.

For those dealing with smaller shipments, shipping less than container load can be an efficient and cost-effective solution. This option allows you to share container space with other shippers, potentially reducing your overall shipping costs.

Which Special Containers Fit Your Unique Cargo?

Refrigerated Containers: The Cool Solution

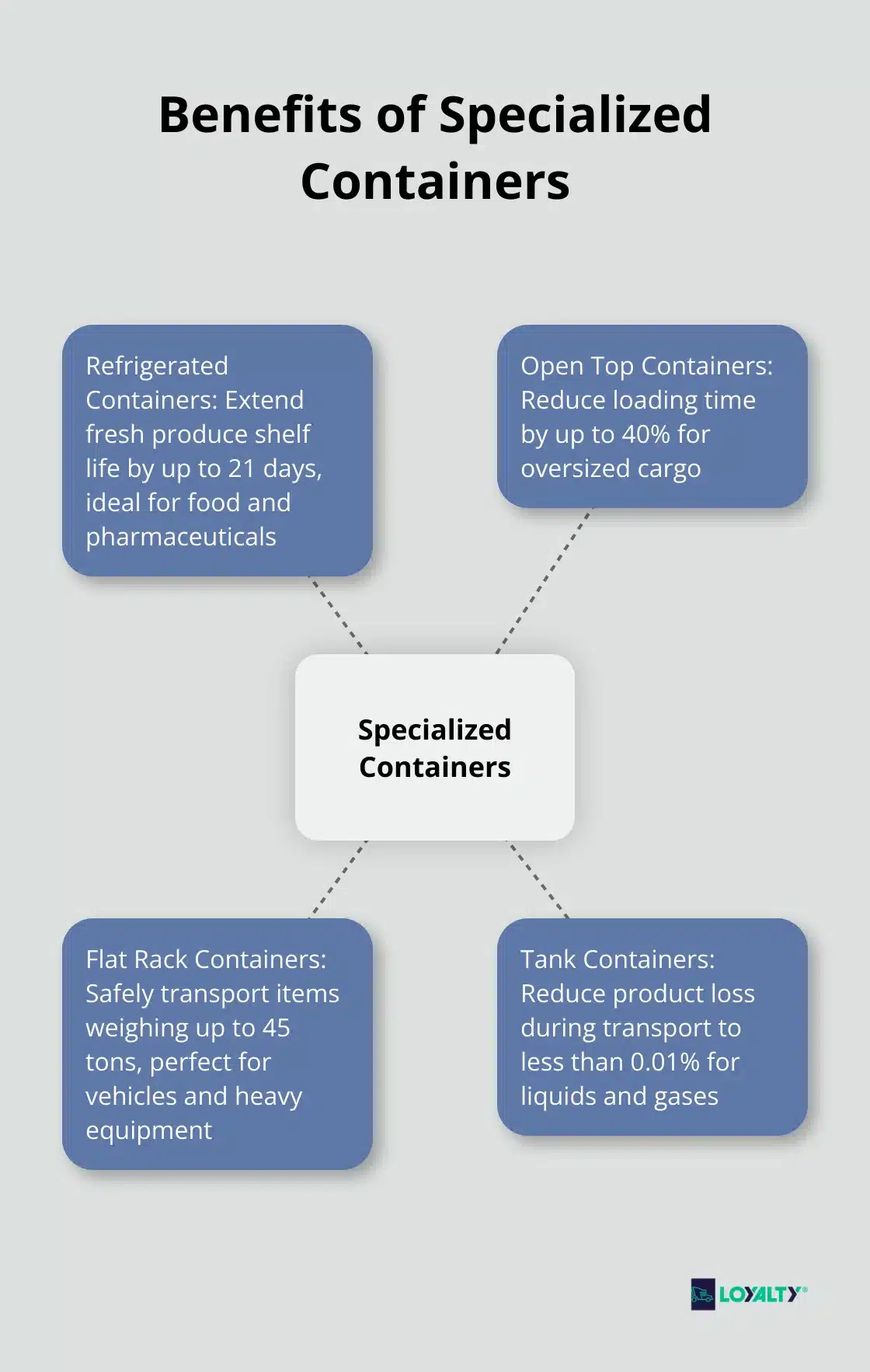

Refrigerated containers (reefers) maintain constant temperatures between -60°C and +30°C (-76°F to +86°F). These containers prove essential for food and pharmaceutical industries. A study in the International Journal of Refrigeration revealed that reefers can extend fresh produce shelf life by up to 21 days compared to non-refrigerated transport. This extension reduces food waste and increases exporter profit margins.

Reefers serve more than frozen goods. The wine industry now uses reefers set at 55°F (13°C) to prevent heat damage during long ocean voyages.

Open Top Containers: Oversized Cargo Solution

Open top containers feature a removable roof, allowing top-loading of bulky items like machinery or large industrial equipment. The Journal of International Logistics and Trade reported that open top containers can reduce loading time by up to 40% for oversized cargo compared to standard containers. This efficiency translates to significant cost savings in port handling fees.

Flat Rack Containers: Heavy Lifting Specialists

Flat rack containers consist of a floor structure with two end walls (fixed or collapsible). They excel at transporting heavy, oversized cargo such as vehicles, boats, or construction equipment. The International Maritime Organization states that flat rack containers can safely transport items weighing up to 45 tons, far exceeding standard container capacity.

Tank Containers: Liquid Cargo Experts

Tank containers transport liquids, gases, and powders. These large cylinders fit within a container frame for easy handling and stacking. The Chemical Distribution Institute notes that tank containers can reduce product loss during transport to less than 0.01% (compared to up to 3% loss when using drums or other packaging methods). This efficiency matters for high-value liquids like specialty chemicals or food-grade oils.

Choosing the Right Specialized Container

Selecting the appropriate specialized container impacts shipping efficiency and cargo safety significantly. Consider your cargo’s specific needs, from temperature control to oversized dimensions. For businesses in manufacturing, automotive, or heavy industry sectors, specialized industrial shipping solutions become crucial for handling complex cargo requirements and ensuring compliance with industry-specific regulations. Try to consult with logistics experts who can provide insights based on experience and data-driven analysis (such as those offered by reputable logistics providers).

Final Thoughts

Sea freight container sizes play a pivotal role in shipping costs, efficiency, and cargo safety. Standard 20-foot and 40-foot containers, along with specialized options like reefers and flat racks, serve specific needs in the global supply chain. Factors such as cargo volume, weight, type, and special requirements must be carefully evaluated when selecting the right container.

The shipping route, distance, and overall cost implications also influence the decision-making process. The cheapest option does not always prove the most cost-effective in the long run. At Loyalty Logistics, we understand the complexities of container selection and its impact on supply chain efficiency.

Our team of experts can guide you through the process, helping you choose the optimal container for your specific needs. With our experience in handling diverse cargo types, we ensure your goods reach their destination safely and on time. Don’t let sea freight container sizes overwhelm you – let Loyalty Logistics be your partner in navigating the world of international shipping.

Choosing the right container size is crucial for optimizing your shipping costs and efficiency. Whether you’re planning regular FCL shipments or need guidance on container selection for your specific cargo type, our logistics specialists are here to help. Get expert container sizing advice today and discover how proper container selection can reduce your shipping costs while ensuring your cargo arrives safely and on time.