Choosing the right lowboy gooseneck trailer can make or break your heavy-hauling operations. At Loyalty Logistics, we understand the critical role these specialized trailers play in transporting oversized and overweight loads, which is why our comprehensive lowboy trailer services are designed to meet the most demanding transportation challenges.

This guide will walk you through the essential factors to consider when selecting a lowboy gooseneck trailer, from load capacity to deck dimensions. We’ll also compare top brands and models to help you make an informed decision for your specific needs.

What Are Lowboy Gooseneck Trailers?

Definition and Design

Lowboy gooseneck trailers are specialized hauling equipment for oversized and heavy loads. These trailers have a distinctive two-drop design with a deck height of 18 to 24 inches above the ground. This low profile allows for a maximum legal load height of up to 11 feet 6 inches in most states, perfect for tall equipment transport.

The gooseneck configuration provides superior weight distribution and stability compared to traditional flatbed trailers. The front of the trailer connects to the truck via a gooseneck that extends over the truck’s rear axle, which improves maneuverability and reduces the overall length of the rig.

Versatility and Efficiency

One of the most significant advantages of lowboy gooseneck trailers is their versatility. Many models come with removable goosenecks (RGN), which can reduce loading times by up to 30% compared to fixed gooseneck models. This feature allows for front-loading of equipment, making it easier to transport machinery that can be driven or rolled onto the trailer.

Choosing the right lowboy trailer aligned with load requirements can enhance fuel efficiency by up to 15% (according to the American Transportation Research Institute). This improvement stems from better aerodynamics and weight distribution compared to flatbed trucking alternatives.

Industry Applications

Construction Sector

In the construction sector, over 80% of firms use lowboy trailers for equipment transport (as reported by the Associated General Contractors of America). These trailers are essential for moving bulldozers, excavators, and other heavy machinery between job sites efficiently and safely.

Oil and Gas Industry

The oil and gas industry heavily relies on lowboy gooseneck trailers, with 70% of oil field equipment moves utilizing this type of trailer (as stated by the American Petroleum Institute). The low deck height is essential for transporting tall drilling equipment while complying with height restrictions on highways.

Safety Considerations

Safety is a top concern in heavy hauling. The National Highway Traffic Safety Administration reports that RGN lowboys have contributed to a 25% reduction in loading-related accidents compared to fixed neck models. This statistic underscores the importance of selecting the appropriate trailer type for specific hauling needs, which is why partnering with experienced heavy haul trucking companies becomes crucial for safe operations.

As we move forward to discuss the factors to consider when choosing a lowboy gooseneck trailer, it’s important to keep these key features and applications in mind.

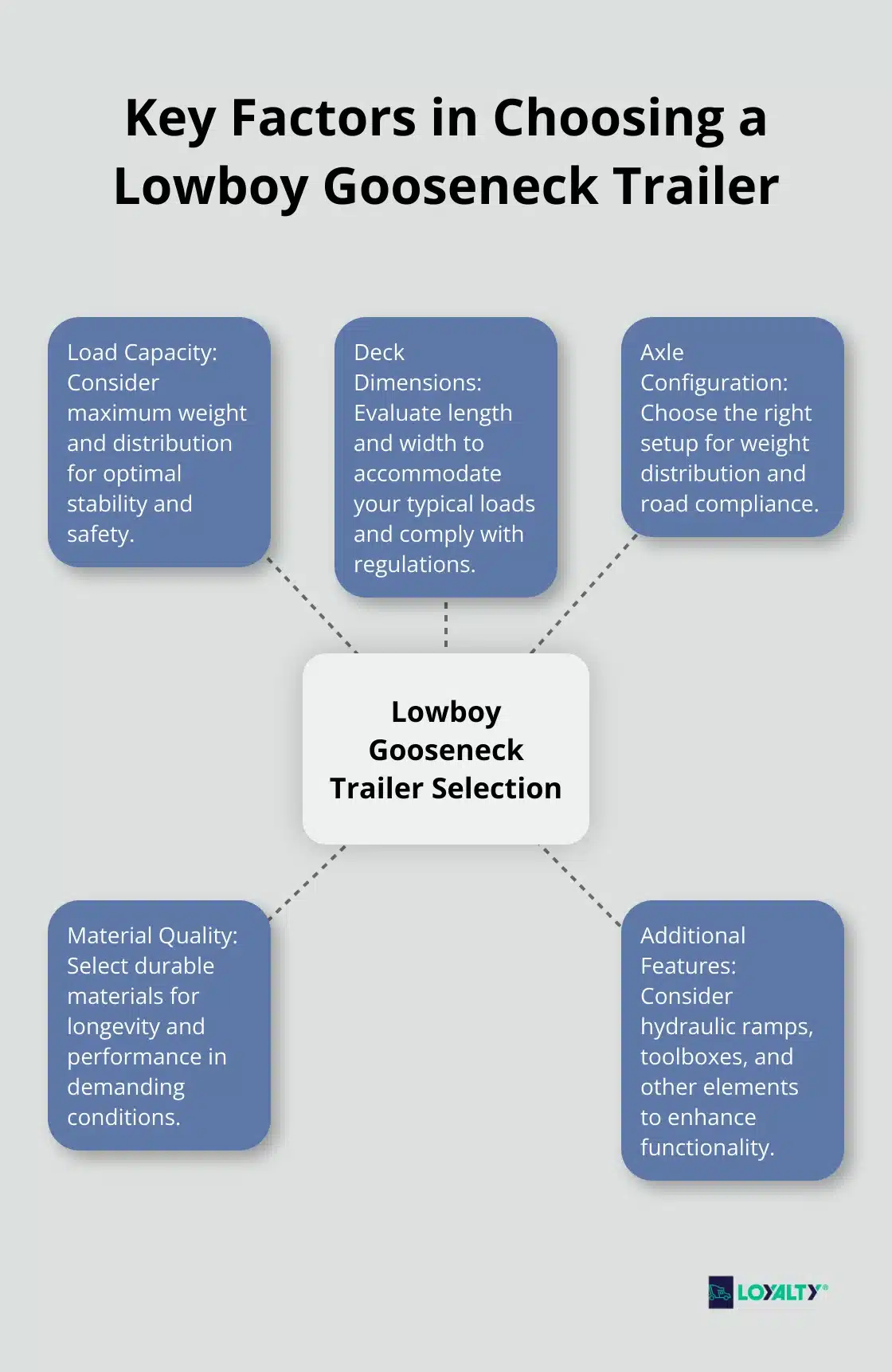

What Factors Matter Most When Choosing a Lowboy Gooseneck Trailer?

Load Capacity and Weight Distribution

The most important factor in selecting a lowboy gooseneck trailer is its load capacity. The Federal Motor Carrier Safety Administration reports that overloading causes 26% of truck-related accidents. This statistic highlights the need to choose a trailer with the right weight capacity for your typical loads.

When you evaluate load capacity, consider both the maximum weight and its distribution. The National Highway Traffic Safety Administration advises that 60% of the load weight should be in the front half of the trailer for optimal stability. Select trailers with adjustable axles to allow better weight distribution and improve stability during transport.

Deck Dimensions and Design

The deck length and width of your lowboy gooseneck trailer determine the types of equipment you can transport. Standard deck lengths range from 24 to 29 feet, but specialized models can extend up to 50 feet. The standard width is typically 102 inches, which accommodates most oversized loads while complying with road regulations.

The deck design also matters. Some trailers feature a beaver tail design, which can cut loading times by up to 15% for certain machinery (according to the American Transportation Research Institute). Also, consider the deck height carefully. A lower deck height enhances stability and simplifies loading and unloading, especially for tall equipment.

Axle Configuration and Suspension System

The axle configuration of your lowboy gooseneck trailer significantly affects weight distribution and road compliance. More axles often provide better weight distribution and stability on the road. However, the best configuration depends on your specific hauling needs and local regulations.

Don’t ignore the suspension system. Air ride suspension can greatly improve ride quality, extend trailer life, and boost fuel efficiency during transport. While it may cost more initially, the long-term benefits in reduced maintenance and improved performance can make it a worthwhile investment.

Material and Construction Quality

The material and construction quality of your lowboy gooseneck trailer directly impact its durability and performance. Steel trailers offer more durability for heavy loads, while aluminum trailers are lighter and can increase fuel efficiency. The construction quality affects the trailer’s longevity and its ability to withstand the rigors of heavy hauling.

Look for trailers with high-grade materials and superior welding techniques. Some manufacturers (like Diamond C) use Grade 100 materials in their Engineered Beam Technology, which provides a stronger yet lighter frame. This results in excellent strength-to-weight ratios, enhancing the trailer’s overall performance.

Additional Features

Consider additional features that can enhance the functionality of your lowboy gooseneck trailer. Hydraulic ramps can speed up loading by up to 40% compared to manual ramps, as indicated by Equipment World magazine. Other useful features include toolboxes for equipment storage, winches for easier loading of non-operational machinery, and LED lighting for improved visibility.

Some manufacturers offer solar charging systems for hydraulic pump batteries, illustrating a focus on convenience and efficiency. These additional features can significantly improve your operational efficiency and make your investment more valuable in the long run, especially when integrated with comprehensive freight shipping services that support industrial manufacturing logistics.

As we move forward to explore the top lowboy gooseneck trailer brands and models, keep these factors in mind. The right combination of these elements will ensure you select a trailer that not only meets your current needs but also adapts to your future hauling requirements.

Which Lowboy Gooseneck Trailer Brands Lead the Pack?

When selecting a lowboy gooseneck trailer, several manufacturers stand out for their quality, innovation, and customer satisfaction. We’ll explore some of the top brands and their popular models to help you make an informed decision.

Diamond C: Engineered for Excellence

Diamond C has established itself with its Engineered Beam Technology, which provides a stronger yet lighter frame than traditional I-Beam designs. Their Fleetneck Engineered Beam 2.0 series, featuring Grade 100 materials, offers exceptional strength-to-weight ratios. Models in this series range from 15,500 lb to 40,000 lb GVWR, catering to a wide array of hauling needs.

A standout feature of Diamond C trailers is the hydraulic dovetail option, with a 12.5-degree approach angle for safer loading of heavy equipment. Their Max Ramps loading style, utilizing 50 ksi steel ramp frames, provides high-strength loading with a 44″ width for added versatility.

Customer reviews often praise Diamond C for their durability and innovative features. Many users appreciate the option for hydraulic disc brakes, which offer superior stopping power and reduced maintenance for high-mileage applications.

Big Tex Trailers: Versatility and Value

Big Tex Trailers offers a range of lowboy gooseneck models that balance quality with affordability. Their 22GN series is particularly popular among contractors and equipment rental companies. These trailers feature a 25,000 lb capacity, 102″ wide deck, and come standard with adjustable suspension for optimal load distribution.

Big Tex stands out for their attention to practical details. For instance, their trailers often include features like stake pockets every 24″ on center, which provide multiple tie-down options for securing diverse loads. Users frequently commend Big Tex for their trailers’ ease of use and reliable performance in demanding conditions.

Felling Trailers: Custom Solutions for Specific Needs

Felling Trailers has built a reputation for offering highly customizable lowboy gooseneck trailers. Their FT-50-3 LP model, for example, can be tailored with various deck lengths, widths, and axle configurations to meet specific hauling requirements.

One of Felling’s strengths is their focus on user-friendly features. Many of their models come with air ride suspension as standard, enhancing ride quality and reducing wear on both the trailer and the transported equipment. Customers often highlight Felling’s responsive customer service and willingness to work on custom solutions.

PJ Trailers: Robust Design for Heavy-Duty Applications

PJ Trailers is known for their heavy-duty designs that stand up to the toughest jobs. Their Low-Pro Flatdeck Gooseneck (LD) series is a favorite among users who regularly transport heavy machinery. These trailers feature a 12″ I-beam main frame and 3″ junior I-beam crossmembers on 16″ centers, providing exceptional structural integrity.

PJ Trailers also offers innovative options like their “Monster Ramps” – hydraulic ramps that are 5′ long and 44″ wide, making loading and unloading of large equipment significantly easier. Users frequently praise PJ Trailers for their durability and ability to handle oversized loads with ease.

Loyalty Logistics: The Top Choice for Comprehensive Solutions

While the aforementioned brands offer quality trailers, Loyalty Logistics stands out as the top choice for comprehensive transportation solutions. With a 98% on-time rate and more than 10,000 successful deliveries, Loyalty Logistics (known for their eco-friendly practices and cost-saving efficiency) provides a level of service that goes beyond just equipment. Their expertise in diverse shipping needs (including refrigerated, reefer, and flatbed options) makes them an ideal partner for businesses seeking a holistic approach to their logistics challenges.

Final Thoughts

Choosing the right lowboy gooseneck trailer requires careful consideration of several factors. Load capacity, weight distribution, deck dimensions, and axle configuration all play vital roles in the trailer’s performance and safety. The material quality and construction of the trailer directly impact its longevity and reliability, making it essential to invest in a well-built model from a reputable manufacturer.

Additional features such as hydraulic ramps or toolboxes can enhance operational efficiency, but they should not overshadow the fundamental aspects of the trailer. It’s important to assess your specific hauling needs and research different models before making a decision. Consulting with an experienced freight broker can provide valuable insights to help you select a lowboy gooseneck trailer that meets your current and future requirements.

For comprehensive transportation solutions, consider partnering with a reliable logistics provider. Loyalty Logistics offers expertise in diverse shipping needs, including refrigerated, reefer, and flatbed options. Their services (which aim for eco-friendly practices and cost-saving efficiency) can help streamline your supply chain and optimize your overall transportation operations.

Ready to find the perfect lowboy gooseneck trailer for your specific hauling needs? Our logistics experts specialize in heavy haul transportation and can help you navigate the complexities of trailer selection, compliance requirements, and route planning. Contact our team today for a personalized consultation and discover how we can optimize your heavy freight operations while ensuring safety and cost-effectiveness.