Choosing the right lowboy trailer can make or break your heavy-hauling operations. At Loyalty Logistics, we understand the critical role these specialized trailers play in transporting oversized or overweight loads.

This guide will help you navigate the various types of lowboy trailers and key factors to consider when making your selection. We’ll explore everything from load capacity to legal requirements, ensuring you find the perfect match for your specific needs.

What Are Lowboy Trailers?

Definition and Purpose

Lowboy trailers are specialized hauling equipment designed for the transport of oversized or overweight loads. These trailers feature a distinctive low deck height (typically 18 to 24 inches off the ground). This low profile accommodates tall machinery and equipment that would exceed legal height limits on standard trailers.

Key Features

The most notable feature of a lowboy trailer is its two-drop design. The deck sits lower than the wheeled axles, creating a well for cargo. This design allows for a maximum legal load height of up to 11 feet 6 inches in most states (significantly higher than conventional flatbed trailers).

Lowboy trailers come equipped with heavy-duty axles, often featuring air-ride suspensions for smoother transport. The number of axles varies based on the trailer’s capacity, with options ranging from two to multiple axles for extreme heavy haul applications.

Common Uses in Transportation

Construction Industry

In the construction sector, lowboy trailers play an indispensable role in moving heavy machinery like excavators, bulldozers, and cranes. The Associated General Contractors of America reports that over 80% of construction firms use lowboy trailers for equipment transport.

Oil and Gas Sector

The oil and gas industry relies heavily on lowboy trailers to transport drilling rigs and other oversized equipment. A study by the American Petroleum Institute found that lowboy trailers are used in 70% of oil field equipment moves.

Selecting the Right Lowboy

When choosing a lowboy trailer, you must consider your specific hauling needs. For instance, if you frequently transport equipment weighing over 80,000 pounds, you’ll need a multi-axle lowboy with a high load capacity. The American Transportation Research Institute reports that matching trailer specifications to load requirements can improve fuel efficiency by up to 15%.

A growing trend in the industry is the use of removable gooseneck (RGN) lowboys. These offer greater versatility in loading and unloading, especially for self-propelled equipment. Industry data shows that RGN lowboys can reduce loading times by up to 30% compared to fixed gooseneck models.

As we move forward, we’ll explore the various types of lowboy trailers available in the market, each with its unique advantages and applications.

Lowboy Trailer Types Explained

Fixed Neck Lowboys

Fixed neck lowboys stand as the workhorses of the heavy hauling industry. These trailers feature a permanent gooseneck connection to the tractor, which offers excellent stability for loads up to 50 tons. Their rigid structure makes them ideal for frequent, heavy-duty transport jobs.

The American Trucking Associations found that fixed neck lowboys are used in 60% of all heavy equipment moves under 50 tons. Their simplicity and reliability make them a top choice for many trucking companies.

However, fixed neck lowboys have limitations. Loading and unloading can present challenges, especially for self-propelled equipment. If your cargo often includes machines that can drive on and off the trailer, you might want to consider other options.

Removable Gooseneck (RGN) Lowboys

RGN lowboys have transformed heavy hauling. These trailers feature a detachable front section, which creates a gentle slope for easy loading of wheeled or tracked equipment. This design reduces loading time and enhances safety.

A report by the National Highway Traffic Safety Administration shows that RGN lowboys have contributed to a 25% reduction in loading-related accidents compared to fixed neck models. This safety improvement alone makes RGNs an attractive option for many haulers.

RGNs also offer versatility. When detached, the trailer can serve as a floating deck, expanding its utility. This feature has increased the popularity of RGNs in the construction and oil industries (where adaptability is key).

Double Drop Lowboys

Double drop lowboys feature two drops in deck height – one behind the gooseneck and another before the wheels. This design allows for an extra-low deck height (typically around 18 inches off the ground).

These trailers excel in transporting exceptionally tall equipment. The Federal Highway Administration reports that double drop lowboys can legally transport loads up to 12 feet in height in most states (a full foot higher than standard lowboys).

However, double drops come with trade-offs. Their complex design makes them heavier and more expensive than single-drop models. They’re best suited for specialized loads that require the extra clearance.

Mechanical vs. Hydraulic Lowboys

The choice between mechanical and hydraulic systems in lowboys can significantly impact your operations. Mechanical systems are simpler and often more reliable, but they require more physical effort to operate.

Hydraulic systems offer easier operation and faster loading times. A survey by Equipment World magazine found that hydraulic lowboys can reduce loading time by up to 40% compared to mechanical models.

However, hydraulic systems are more complex and can be more prone to maintenance issues. They’re also typically more expensive upfront. Consider your budget, frequency of use, and the physical capabilities of your team when making this choice.

As we move forward to discuss the factors to consider when choosing a lowboy trailer, keep these different types in mind. Each type has its strengths and weaknesses, and understanding these will help you make an informed decision that best suits your specific hauling needs.

What Factors Matter Most When Choosing a Lowboy Trailer?

Load Capacity and Weight Distribution

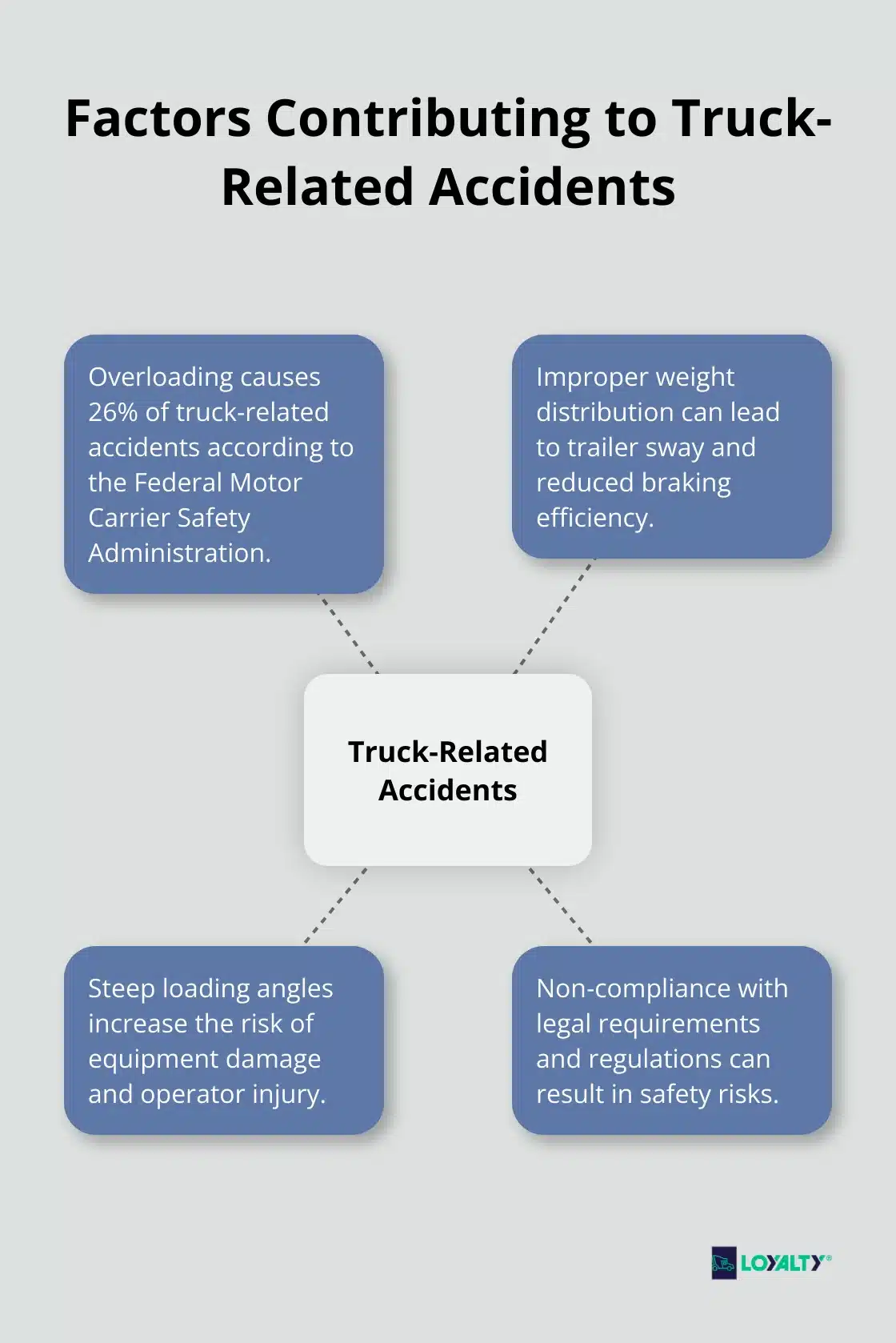

The most important factor in choosing a lowboy trailer is its load capacity. This determines the maximum weight your trailer can safely carry. The Federal Motor Carrier Safety Administration reports that overloading causes 26% of truck-related accidents. Always select a trailer with a capacity that exceeds your heaviest anticipated load by at least 20%.

Weight distribution is equally important. Improper distribution can cause trailer sway, reduced braking efficiency, and increased tire wear. The National Highway Traffic Safety Administration recommends that 60% of the load weight should be in the front half of the trailer. Many modern lowboys have adjustable axles to help achieve optimal weight distribution.

Deck Dimensions and Design

The length and width of the deck directly impact what you can haul. Standard lowboy trailers range from 24 to 29 feet in deck length, but specialized models can extend up to 50 feet. Width typically varies between 8.5 to 10 feet.

Consider your typical loads when choosing dimensions. If you often transport wide loads, opt for a trailer with extendable outriggers. These can increase the deck width by up to 2 feet on each side, providing extra space for oversized equipment.

The deck design also matters. Some lowboys feature a “beaver tail” – a sloped rear section that reduces the loading angle. This can be important for equipment with low ground clearance. The American Transportation Research Institute reports that beaver tail designs can reduce loading times by up to 15% for certain types of machinery.

Ground Clearance and Loading Angle

Ground clearance is an often-overlooked factor that can significantly impact your operations. Lower deck heights (around 18 inches) are ideal for extremely tall loads but may pose challenges on uneven terrain. Higher deck heights (24-26 inches) offer better ground clearance but reduce the maximum legal load height.

The loading angle is important, especially for self-propelled equipment. A steeper angle increases the risk of equipment damage and operator injury. The Occupational Safety and Health Administration recommends a maximum loading angle of 15 degrees for most heavy equipment. Hydraulic goosenecks and adjustable ride height systems can help achieve optimal loading angles across various situations.

Compatibility with Your Truck and Equipment

The lowboy trailer you choose must be compatible with your truck and the equipment you plan to transport. Consider the following:

- Truck capacity: Ensure your truck can handle the combined weight of the trailer and its load.

- Hitch type: Match the trailer’s hitch to your truck’s towing system.

- Electrical connections: Verify that the trailer’s lighting and brake systems are compatible with your truck.

Try to choose a trailer that offers flexibility for different types of loads (this can save you money in the long run).

Legal Requirements and Regulations

Understanding and complying with legal requirements is essential when selecting a lowboy trailer. Different states have varying regulations regarding trailer dimensions, weight limits, and required safety features.

The Federal Highway Administration sets national standards, but local regulations can be more stringent. For example, some states require additional lighting or reflective markings on trailers over certain lengths.

Always check the specific regulations in the areas where you’ll be operating. Non-compliance can result in hefty fines and potential safety risks. (It’s worth consulting with a transportation lawyer or expert to ensure full compliance.)

Final Thoughts

Selecting the right lowboy trailer will significantly impact your heavy hauling operations. You must consider load capacity, deck dimensions, ground clearance, and compatibility with your existing equipment to ensure your chosen trailer meets your specific needs. Legal requirements and regulations also play a vital role in your decision-making process, as compliance ensures safety and helps avoid fines.

The type of lowboy trailer you choose should align with the nature of your loads and the frequency of your operations. Fixed neck, removable gooseneck, and double drop trailers each offer unique advantages for different hauling scenarios. Understanding these differences will help you make an informed decision that serves your business well for years to come.

At Loyalty Logistics, we understand the complexities involved in choosing the right lowboy trailer. Our team can provide valuable insights to help you navigate this important decision. With our experience in versatile and sustainable transportation solutions, we can assist you in finding the perfect lowboy trailer that meets your specific hauling needs (while optimizing your supply chain efficiency).

Need a lowboy trailer for your next oversized shipment?

We support industrial manufacturers with specialized freight across North America: