The logistics industry is undergoing a green revolution. At Loyalty Logistics, we’re witnessing firsthand how eco-friendly innovations are reshaping supply chains worldwide.

From sustainable transportation to green shipping practices, these advancements are not only reducing environmental impact but also improving operational efficiency. This blog post explores the cutting-edge solutions driving this transformation and their far-reaching effects on the future of logistics.

How Can We Make Transportation Greener?

Transportation in logistics is undergoing a green revolution. The industry is rapidly evolving, with sustainable solutions at the forefront of this change.

Electric and Hybrid Vehicles: Powering the Future of Logistics

Electric and hybrid vehicles are transforming the logistics sector. Medium- and heavy-duty vehicles make up less than 5% of vehicles on the road, but they create over 20% of carbon emissions from the transportation sector. The industry witnesses a surge in the adoption of these eco-friendly alternatives.

Major players like UPS and FedEx invest heavily in electric fleets. UPS, for instance, has ordered 10,000 electric delivery vans from Arrival (set to deploy by 2024). This shift reduces emissions and cuts operational costs. Electric vehicles require less maintenance and can save up to 70% on fuel costs compared to their diesel counterparts.

Biofuels: Bridging the Gap to Sustainable Logistics

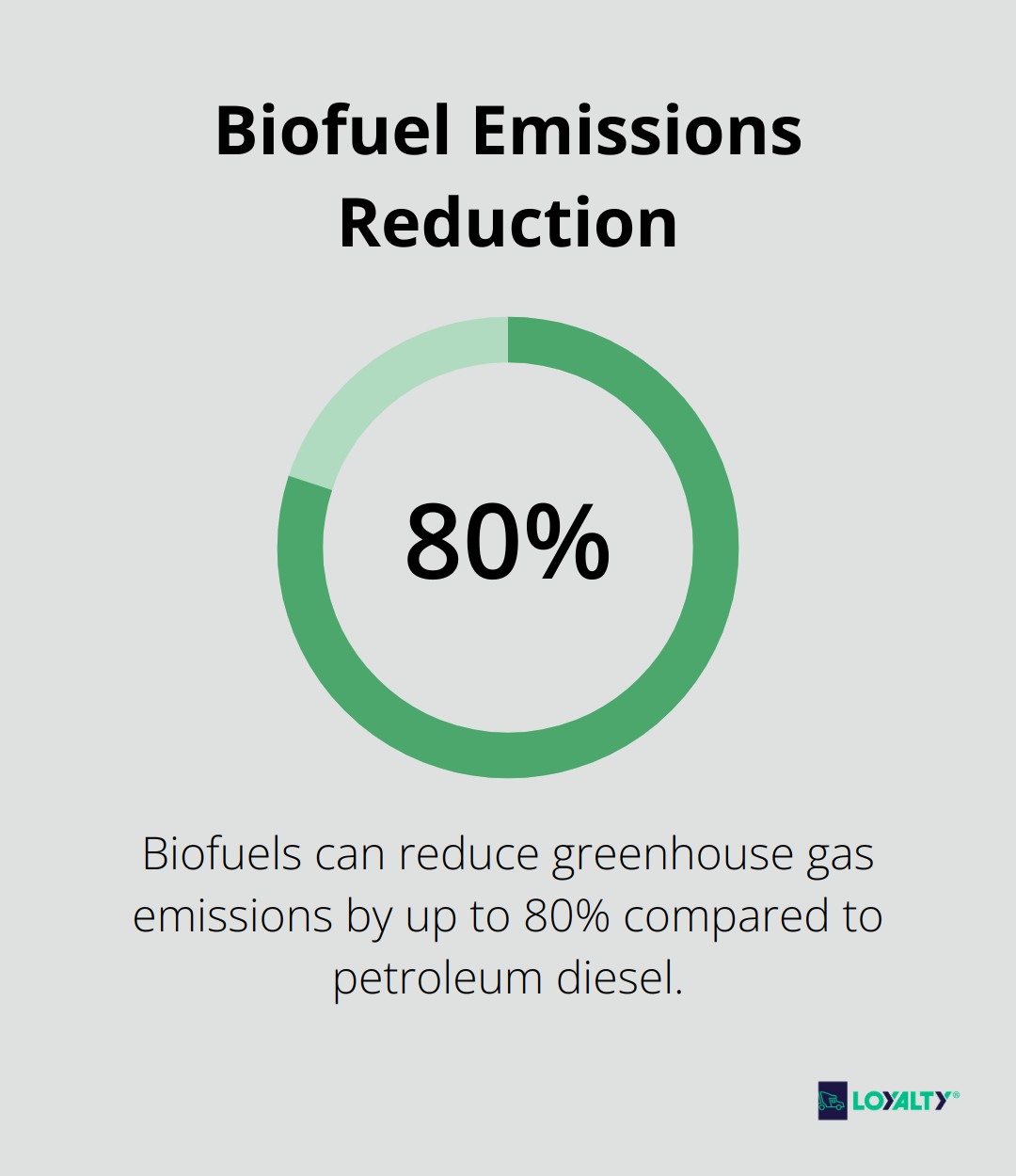

While electric vehicles gain traction, biofuels offer an immediate solution for existing fleets. Biodiesel and renewable diesel grow increasingly popular in the logistics industry. These fuels can reduce greenhouse gas emissions by up to 80% compared to petroleum diesel (according to the U.S. Department of Energy).

Companies like Neste lead the charge in producing renewable diesel from waste and residue raw materials. This approach not only reduces emissions but also promotes a circular economy. Many logistics providers explore partnerships with biofuel producers to further reduce their carbon footprint.

Beyond environmental impact, eco-friendly logistics can elevate brand reputation and attract like-minded partners. Discover how reforestation is becoming part of this shift in our post on sustainable logistics and supply chain innovation.

Smart Route Planning: Efficiency Meets Emission Reduction

Route optimization serves as a powerful tool in reducing emissions. Advanced AI and machine learning algorithms analyze traffic patterns, weather conditions, and delivery schedules to determine the most efficient routes.

At Loyalty Logistics, we go a step further by rewarding sustainability. Our Loyalty Green Rewards Program helps customers earn points by choosing greener freight options and reinvesting in environmental impact.

UPS’s ORION (On-Road Integrated Optimization and Navigation) system exemplifies this technology. It saves approximately 10 million gallons of fuel annually, reducing CO2 emissions by 100,000 metric tons. This technology not only cuts emissions but also improves delivery times and reduces operational costs.

Many logistics companies implement similar systems, with initial results showing significant reductions in fuel consumption (often around 15%) and improvements in delivery efficiency (up to 20%). These improvements translate directly into cost savings for clients and a reduced environmental impact.

The transition to sustainable transportation is not just an environmental imperative; it’s a business necessity. As regulations tighten and consumer demand for eco-friendly practices grows, companies must adapt or risk obsolescence. These innovations not only reduce environmental impact but also position forward-thinking logistics providers for long-term success in an increasingly sustainability-focused market.

The next frontier in green logistics lies in warehousing and packaging. Let’s explore how companies are revolutionizing these aspects to create truly sustainable supply chains.

How Warehouses Are Going Green

Energy-Efficient Warehouse Design

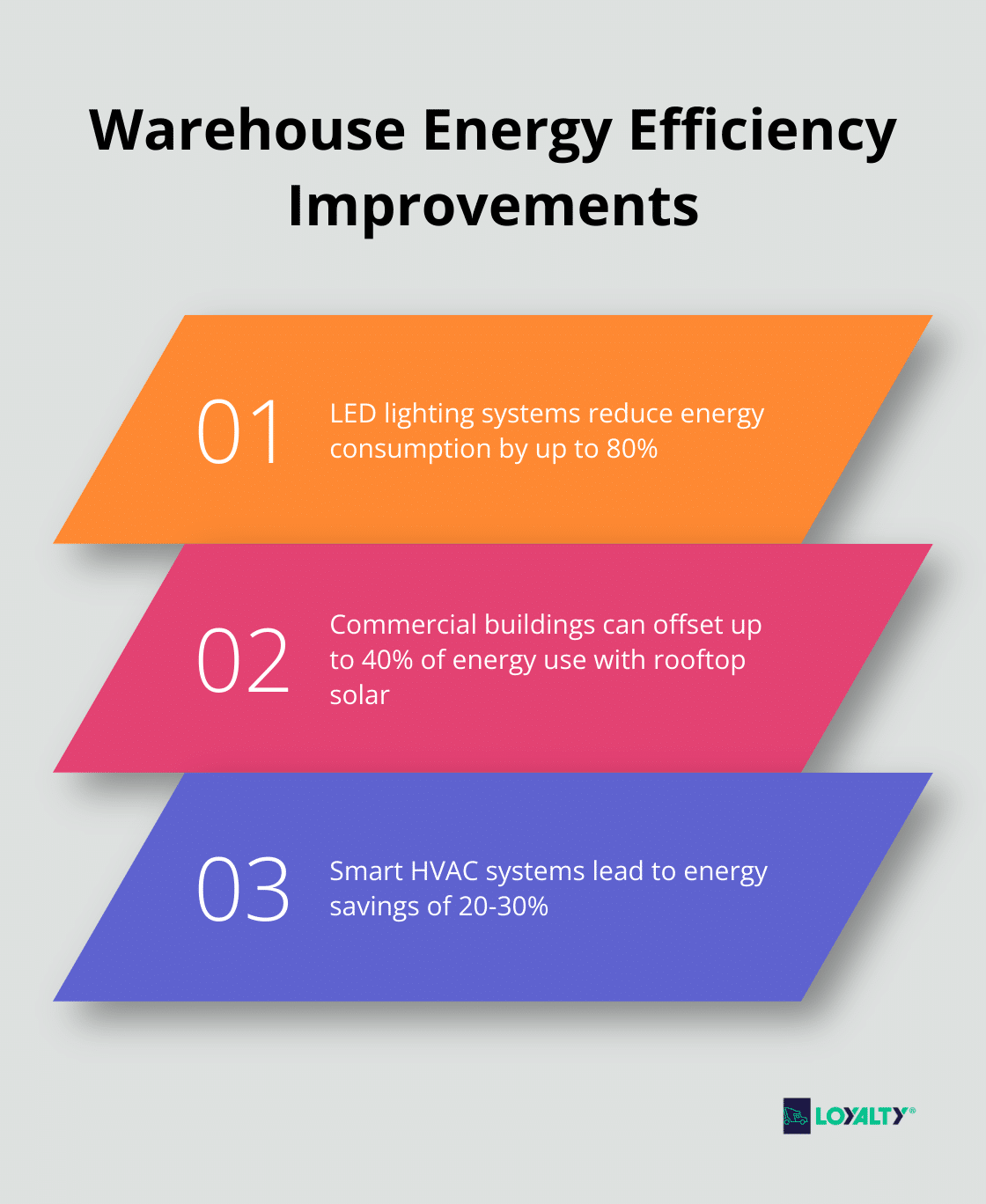

Modern warehouses transform into energy efficiency powerhouses. LED lighting systems with motion sensors reduce energy consumption by up to 80% compared to traditional lighting. These systems not only cut costs but also improve working conditions for staff.

Solar panels revolutionize warehouse energy use. The U.S. Department of Energy reports that commercial buildings can offset up to 40% of their energy use with rooftop solar installations. Some warehouses even achieve net-zero energy status, producing as much energy as they consume.

Smart HVAC systems optimize temperature control with AI, reducing energy waste. These systems lead to energy savings of 20-30% (according to the American Council for an Energy-Efficient Economy).

Sustainable Packaging Materials

The packaging industry shifts towards sustainability. Biodegradable materials made from cornstarch, mushroom roots, and seaweed replace traditional plastics. These materials break down naturally, leaving no harmful residues.

Reusable packaging solutions rise in popularity. Companies partner with major brands to create durable, reusable containers for various products. This approach reduces waste and builds customer loyalty through deposit systems.

Corrugated cardboard remains a staple, but with improvements. Many companies now use 100% recycled cardboard, and some experiment with grass-based paper as an even more sustainable alternative.

Waste Reduction and Recycling Programs

Zero-waste warehouses become a reality. Advanced sorting systems use AI and robotics to separate recyclables with unprecedented accuracy. These systems process up to 80 tons of material per hour, recovering valuable resources that would otherwise end up in landfills.

Reverse logistics plays a key role in waste reduction. Companies efficiently manage returns and recycle old products, recovering valuable materials and reducing their overall environmental impact. Some electronics manufacturers now recover up to 90% of the materials from their old products.

Composting programs for organic waste gain traction in warehouses. Food distributors and grocery chains lead this charge, turning what was once considered waste into valuable soil amendments.

The green warehouse revolution creates more efficient, cost-effective operations that meet the growing demand for sustainable practices. As innovation continues in this space, the entire supply chain reshapes for a greener future. The next frontier in eco-friendly logistics lies in leveraging technology to drive sustainability across the entire supply chain.

How Technology Revolutionizes Eco-Friendly Logistics

Technology transforms the logistics industry, propelling sustainability to new heights. Three key technologies lead this transformation: Internet of Things (IoT), Artificial Intelligence (AI), and blockchain. These innovations reshape resource management, equipment maintenance, and supply chain transparency.

IoT: Smart Sensors for Sustainable Logistics

IoT devices function as the nervous system of modern logistics operations. These smart sensors collect real-time data on fuel consumption, warehouse temperatures, and more. DHL’s SmartSensor technology monitors temperature-sensitive shipments, which reduces spoilage and waste. This approach cuts costs and minimizes the environmental impact of damaged goods.

In warehouses, IoT sensors optimize energy use. They adjust lighting and HVAC systems based on occupancy and activity levels. These sensors also monitor inventory levels, which reduces overstock situations and associated waste.

AI and Machine Learning: Predictive Maintenance for Sustainability

AI and machine learning algorithms transform maintenance practices in logistics. Predictive maintenance, powered by these technologies, anticipates equipment failures before they occur. This proactive approach extends the lifespan of vehicles and machinery, which reduces the need for replacements (and the associated environmental impact of manufacturing new equipment).

UPS uses AI to predict when vehicle parts will fail. This system has reduced breakdowns and extended the life of their fleet, which significantly lowers their carbon footprint.

AI also optimizes loading processes. These systems analyze historical data and current orders to determine the most efficient way to pack trucks. This approach reduces the number of trips needed and cuts fuel consumption.

Blockchain: Transparency in Sustainable Supply Chains

Blockchain technology brings unprecedented transparency to supply chains. This decentralized ledger system allows every stakeholder to track products from source to destination, which ensures compliance with sustainability standards.

Walmart uses blockchain to trace the origin of food products. This system reduces food waste and improves safety. In case of contamination, they can now trace a product’s journey in seconds instead of days, which minimizes the amount of food that needs to be discarded.

For companies focused on ethical sourcing, blockchain provides a tamper-proof record of a product’s journey. This technology allows consumers to verify claims about sustainable practices, which builds trust and drives demand for eco-friendly products.

The integration of these technologies creates smarter, more efficient, and ultimately more sustainable logistics operations. As these systems become more sophisticated and widely adopted, we expect to see significant reductions in waste, energy consumption, and emissions across the entire supply chain.

Final Thoughts

The eco-friendly innovations transforming supply chains drive remarkable improvements in efficiency and cost-effectiveness. Electric vehicles, smart route planning, and sustainable warehousing practices slash fuel consumption and emissions while boosting operational performance. These advancements reshape the logistics landscape, creating leaner, greener, and more responsive supply chains.

We anticipate further integration of AI and IoT technologies to optimize resource management and predictive maintenance. Blockchain will play an increasingly vital role in ensuring transparency and traceability across supply chains. We expect to see a surge in green shipping practices, with more companies adopting carbon-neutral delivery options and investing in alternative fuels.

Loyalty Logistics leads this green revolution in the logistics industry. Our sustainable transportation solutions and innovative Loyalty Green Rewards program demonstrate our dedication to eco-friendly practices. Companies that choose partners like us can significantly reduce their environmental impact while improving their supply chain efficiency.

Want to turn your logistics into a sustainability advantage?

We help you reduce emissions, cut costs, and build a greener brand—all while moving freight efficiently: